Photo analysis Systems

Because you can’t manage what you can’t measure!

WipWare designs and manufactures industry leading photo analysis software and hardware that offers real-time analysis of materials in the field, laboratory, on-line production settings for underground and surface mining, quarries, aggregate production, forestry, coal industries and many more. WipWare offers stationary and mobile systems for conveyors, haulage trucks and site-specific locations. WipWare’s Photo analysis systems have helped companies world-wide save millions of dollars by preventing equipment down-time, improving productivity, enhancing personnel health and safety and optimizing processes.

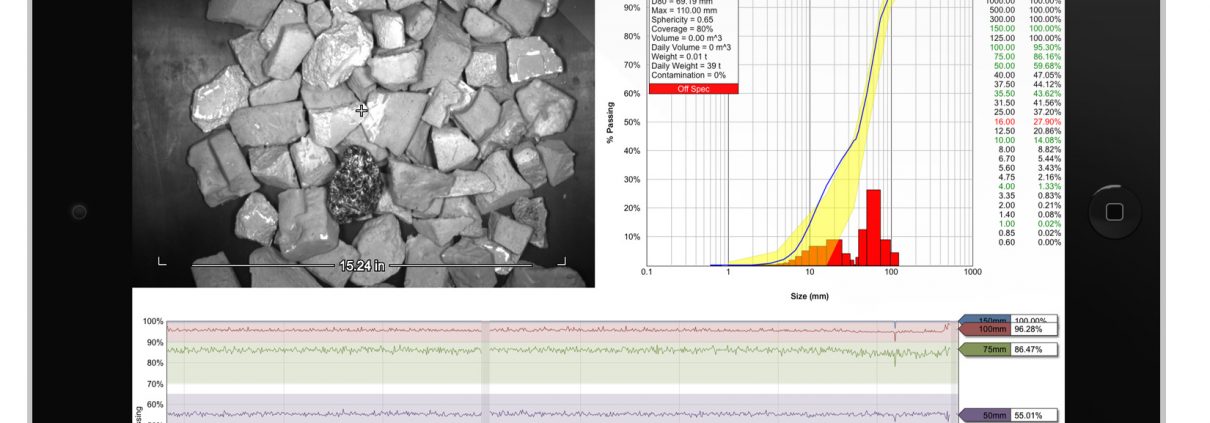

WipFrag

Analyze your fragmentation with the particle sizing software that started it all! Optimize blast performance using photographs. From desktop to tablet; WipFrag 4 puts particle sizing at your fingertips!

Available for Windows PC, Apple IOS and Android devices.

WipWare technology empowers you with the tools you need to collect historical data, establish a statistical baseline and track subtle changes throughout the optimization process so you can make decisions based on fact instead of theory.

As proven in the mining, forestry and aggregate industries, WipFrag particle analysis helps:

- Cut downstream energy costs

- Improves efficiency

- Benchmark and optimize blast performance

See the video: General WipFrag video

Solo

Solo is a completely automated analysis instrument for measuring the size distribution of unconsolidated material on conveyor belts in real time without disrupting production. This technology is autonomous and performs well in harsh industrial environments for process automation, historical reference or direct control. The latest generation of Solo adds the ability to provide volume statistics (when combined with a belt weightometer) and detect contamination. Results can be accessed remotely through desktop computer or at your fingertips with an iOS device.

Improve SAG throughput, evaluate crusher performance, detect broken screens, and discover contamination.

Benefits include

- Non-Contact

- Non-Disruptive

- Fully Automated

- Establish Quality Control

- Characterize Material

- High Accuracy

- Improve Safety

- Increase Efficiency

- Increase Throughput

- Objective Quantification

- Detect Irregularities

- Real Time Results

- Reduce Equipment Downtime

- Reduce Maintenance

- Reduce Waste

Reflex

Reflex is an automated real-time fragmentation analysis instrument designed to measure particle fragmentation on moving LH or LHD vehicles without disrupting production. This technology is autonomous and performs well in harsh industrial environments for blast optimization, historical reference or direct control.

When a vehicle is detected, the origin of the material is determined and the camera begins acquiring image samples. Proprietary edge detection is used to render a polygon network around each particle to instantly generate material specifications such as size distribution, uniformity, shape and more in real time.

MailFrag

Get complete analysis results in less than 48 hours after uploading photographs of material to our MailFrag service. Each image can be analysed separately or we can merge results from several images to provide a comprehensive report on your material.

MailFrag is an online fragmentation analysis service which allows you to experience firsthand the effectiveness of WipWare Photoanalysis technology. The leaders in the field will provide accurate, easy to read reports. MailFrag is second to none for speed, accuracy, repeatability, objectivity, and cost. The service is quick and affordable. Simply send us your images and we’ll promptly return you the particle sizing data. We can accept as many images as your study requires through our secure FTP site. You have the images, we have the answers!

See the video: WipWare MailFrag video